Designing custom jewelry and providing repair services are among the most profitable, yet most complex, areas for jewelry businesses. These processes also carry the greatest potential for error if custom order tracking is inadequate. Faulty tracking can lead to delays, misunderstandings, material loss, and, worst of all, dissatisfied customers.

We present the 5 most common mistakes that can ruin your custom order process and how to avoid them using a dedicated jewelry repair software solution.

The 5 critical mistakes and how to fix them

Mistake 1: the communication gap and customer anxiety

The most common mistake is that the customer only receives information when dropping off and picking up the item. During the long manufacturing or repair process, the customer becomes anxious and makes unnecessary calls to the store to find out what is happening with their valuable jewelry. This not only results in a poor customer experience but also wastes staff time.

The Solution: The key is to implement a system that provides real-time, automated status updates to the customer, such as an online portal or automated notifications, to ensure transparency and reduce inbound calls.

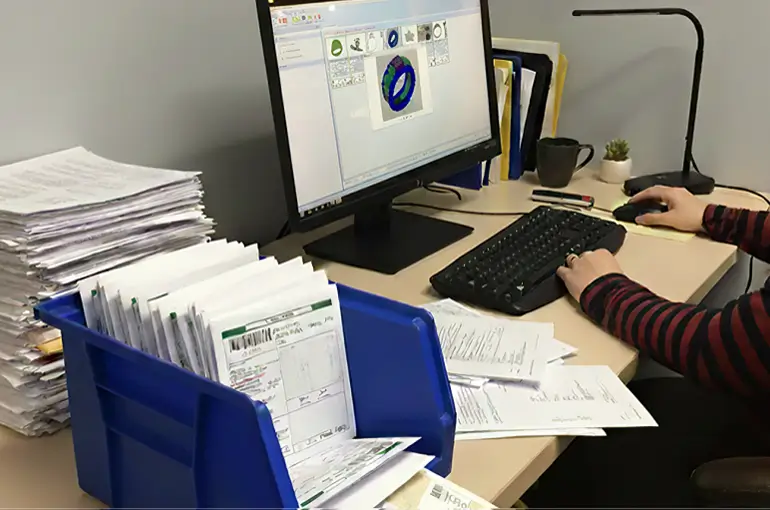

Mistake 2: the chaos of the "paper-based order management"

Many stores still try to manage repair instructions, material lists, and sketches using paper-based work orders, scattered digital files, and emails. This manual system signifies a lack of job bag management, which can easily lead to lost instructions, the use of incorrect materials, and a critical slowdown in the workflow.

The Solution: A digital Job Bag Management system is essential. All information photos, sketches, materials, deadlines, and approvals - must be stored digitally and centrally. Implementing a barcode or QR code system can ensure the job moves seamlessly through the workshop, with staff always accessing the latest, accurate data.

Mistake 3: inaccurate material and inventory tracking

One of the biggest challenges in custom orders is the precise tracking of raw materials. If you don't accurately track how much gold, stone, or other raw material was used, it leads to inaccurate cost calculation, inventory shortages, or unnecessary material waste. This directly impacts your profit margin. The

Solution: A dedicated inventory system must be used to track raw materials by weight and quantity. The system should automatically deduct used materials from the inventory, ensuring accurate cost calculation and preventing material loss, and account for loss tracking. This is crucial for maintaining profit margins.

Mistake 4: promising unrealistic deadlines

Sales staff often promise overly optimistic deadlines to the customer without having a real-time view of the workshop's current workload and manufacturing steps. This mistake leads to delays, customer complaints, and an overburdened workshop staff.

The Solution: Implementing a Workflow Tracking system is vital. It must provide a real-time overview of the workshop's capacity and the status of ongoing jobs. This allows sales staff to set realistic deadlines based on the actual manufacturing steps (e.g., casting, polishing, stone setting) and capacity, rather than guesswork.

Mistake 5: lack of internal accountability and responsibility

If it's unclear who is responsible for a specific workflow step (e.g., stone sourcing, casting, polishing), the work stalls, tasks are forgotten, and finger-pointing begins. This internal friction slows down the process and damages morale.

The Solution: A robust tracking system must allow for assigning a responsible person to every single task. The system should record who did what and when, ensuring complete transparency and accountability throughout the entire process.

Conclusion

Managing custom orders and repairs doesn't have to be a headache. The 5 critical mistakes above can be avoided by implementing the right technology.

A dedicated jewelry repair software offers a solution to all these challenges, helping you increase efficiency, maintain your profit margin, and improve the customer experience.

Ready to fix these mistakes?

Software like PIRO is specifically designed to address these 5 critical issues, providing the digital tools for seamless custom order tracking and job bag management.

Request a demo today and make your custom order process seamless!

Frequently asked questions (FAQ)

- How does PIRO help with the "Communication Gap" (Mistake 1)?

PIRO offers an Order Status Tracking feature that allows customers to check the real-time status of their custom order or repair online. It also automates email and SMS notifications for status changes, significantly reducing the need for customers to call the store for updates. - Can PIRO manage my raw materials and precious stones inventory?

Yes. PIRO's Production Module and Inventory Tracking are specifically designed for the jewelry industry. They allow for the precise tracking of raw materials (like gold, silver, and loose diamonds) by weight and quantity, ensuring accurate cost calculation and minimizing material loss on custom jobs. - Is PIRO suitable for both retail and manufacturing/workshop operations?

Absolutely. PIRO is an all-in-one jewelry management software that includes both a modern POS (Point of Sale) system for retail and a sophisticated Workshop Management module. This integration ensures seamless data flow from the sales counter to the production floor. - How does PIRO ensure realistic deadlines for custom orders?

PIRO's Workflow based order Tracking provides a real-time visual overview of the manufacturing steps (e.g., casting, setting, polishing) and the status of every job in the production pipeline with real time due date estimates like deadlines for manufacturing and delivery. - Does PIRO support multi-location inventory management?

Yes. PIRO supports multi-location inventory management, allowing retailers and wholesalers to track stock across multiple stores, warehouses, and even consignment (memo) inventory, all within a single, integrated system.