Digital jewelry inventory management is the first step towards automation

An inventory that falls short translates to lost sales opportunities, while a surplus inventory entails unnecessary operational costs in terms of handling, transportation, and storage. If some of the scenarios described below are familiar that it is a good sign that your organization needs a new jewelry inventory software.

- Have you ever met the problem where you couldn’t tell what raw materials or products you have in your inventory?

- Ever been in a situation whereby the time you collected all these information, would be outdated because in the meantime other inventory movements would occur?

- Is it difficult to calculate the total value of your actual inventory?

- Or is it difficult to calculate how much raw material you will be needing for the production of your jewelry orders?

You can see from the previous questions that tracking your jewelry inventory is a complex problem. This gets particularly high importance in the jewelry industry because we’re talking about high-value items and materials. Whatever type of business may it be – manufacturer, retailer, wholesaler -, tracking your inventory is crucial. You might say that this is the heart of the business that makes everything else go around. It correlates with manufacturing, sales, stocks of raw material, reordering, consignments – therefore it cannot be handled as an isolated feature. This is why legacy inventory software isn’t suitable to complete this complex task because they aren’t dynamically connected to the other activities.

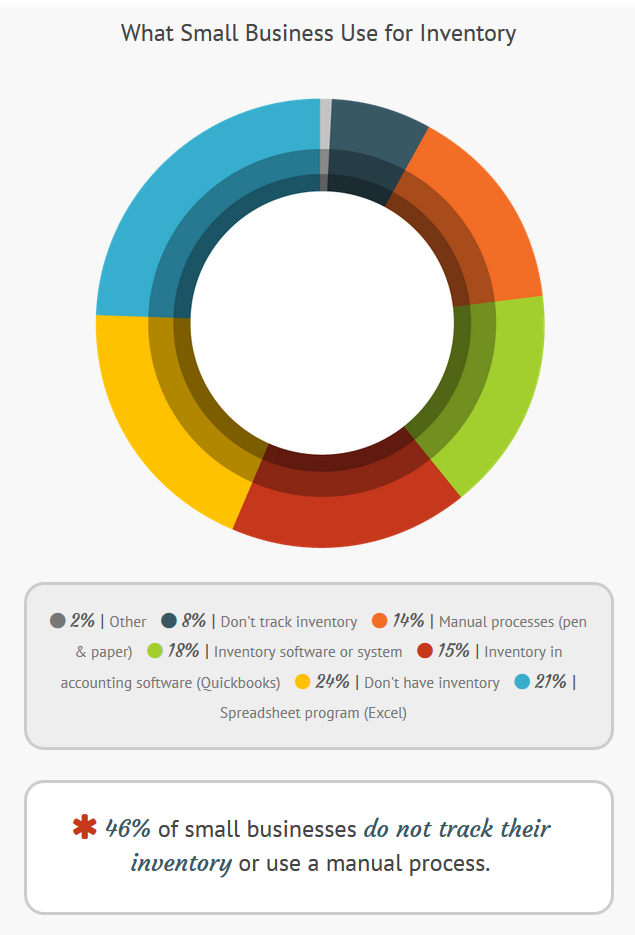

Excel spreadsheets? They may work for a one-man company, but for those who track their inventory this way, I don’t have to tell you about the solution’s obvious disadvantages.

I have brought you some very suggestive data related to this: in the US among small businesses, 46% did not have an automated inventory management system.

(source)

Benefits of a jewelry inventory software

Let’s quickly mention the crucial goals that we can achieve with an inventory management module:

- Optimal levels of inventory – achieve optimal levels of inventory at the right locations

- Reduce inventory losses – address issues of inventory losses and obsolescence

- Reduce the problem of excessive inventory

- Forecasting – prevent interruptions to production caused by stock shortages

- Increase visibility – increase the visibility of information about inventory

- Improve procurement and replenishment processes

- Manage inventory valuations and costs

- Monitor sales and production trends

- Manage online sales

Each bullet point would worth a longer explanation on its own, but those who have faced these problems before knowing exactly which of these features mentioned before are important and why. It might be more valuable if I talk about how an inventory software or module can contribute to achieving these goals. After all, we all know the problems, but you a probably wondering about the solution, right?

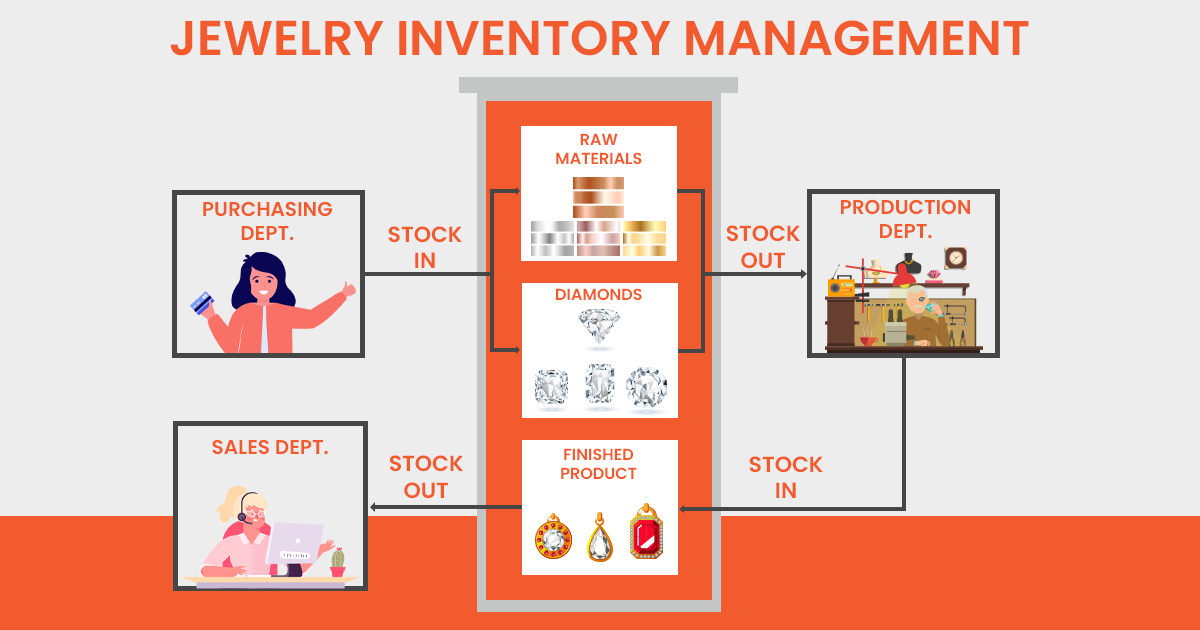

Jewelry inventory handling in reality

How is jewelry inventory handling happening in reality? To get a better understanding, it makes sense to approach this from several different points of view - from the perspective of sales, manufacturing, purchasing, accounting and handling raw materials, even from the perspective of pricing.

#7 Vlog on Next Level Jewelry with Zsolt Torok

Subscribe to this YouTube channel

A. Jewelry inventory management from a sales viewpoint

From a sales perspective, one of the simplest questions is: what do we have on the stock that can be sold immediately? This can be easily followed in inventory management software thanks to the fact that items can be sorted into different groups for the sake of transparency: pendants, rings (engagement rings, wedding bands, solitaire rings), earrings, etc. In addition to this, the groups have attributes linked to them that are specific to each group. For example length for pendants, size for rings.

The second question from a sales perspective is where is the jewel located? In the safe? In the retail store? In another location? This is why inventory locations were made.

This is where the question of consignments (or memos) comes up. Since these usually cannot be solved by assigning a simple inventory location, they require an optimized feature that is part of the inventory handling but still handles the items sent out for consignment separately.

It may also be important to know from a sales point of view what pieces of jewelry are sold frequently and which pieces have been left in the inventory for a long time.

Last, but not least, how our POS system is connected to the back-office inventory system is also an important question. If we, for example, track our stocks in an Excel spreadsheet, what kind of procedure do we need to use, in order to remove the piece of jewelry that has just been sold, from our inventory? If this cannot be done in as many as two steps, then we’re losing precious time, this is one of the reasons why it is worth automating this step. Let’s not forget e-commerce platforms either, especially since it is becoming a more and more mainstream sales channel and we meet the question of integration very often. It is almost impossible to build an online sales strategy if the inventory is being tracked manually in the background.

The solution is integrating the online platform with the jewelry inventory software or ERP software, this way orders will sync automatically and inventory can be kept up-to-date on both ends without any particular effort.

This integration also provides you with:

- Increase visibility

- Optimal levels of inventory

- Monitoring sales trends

- Managing online sales

B. Jewelry inventory management from the manufacturing viewpoint

As I mentioned before, inventory is the engine of business processes. Unfit inventory management can make production cumbersome, therefore these two are closely correlated.

First of all, it is important to track the inventory ledger accurately. What raw materials do I have in stock and how do I know if I need to order more? If there’s no central database for this, it can be extremely difficult to follow the inventory due to the constant fluctuation.

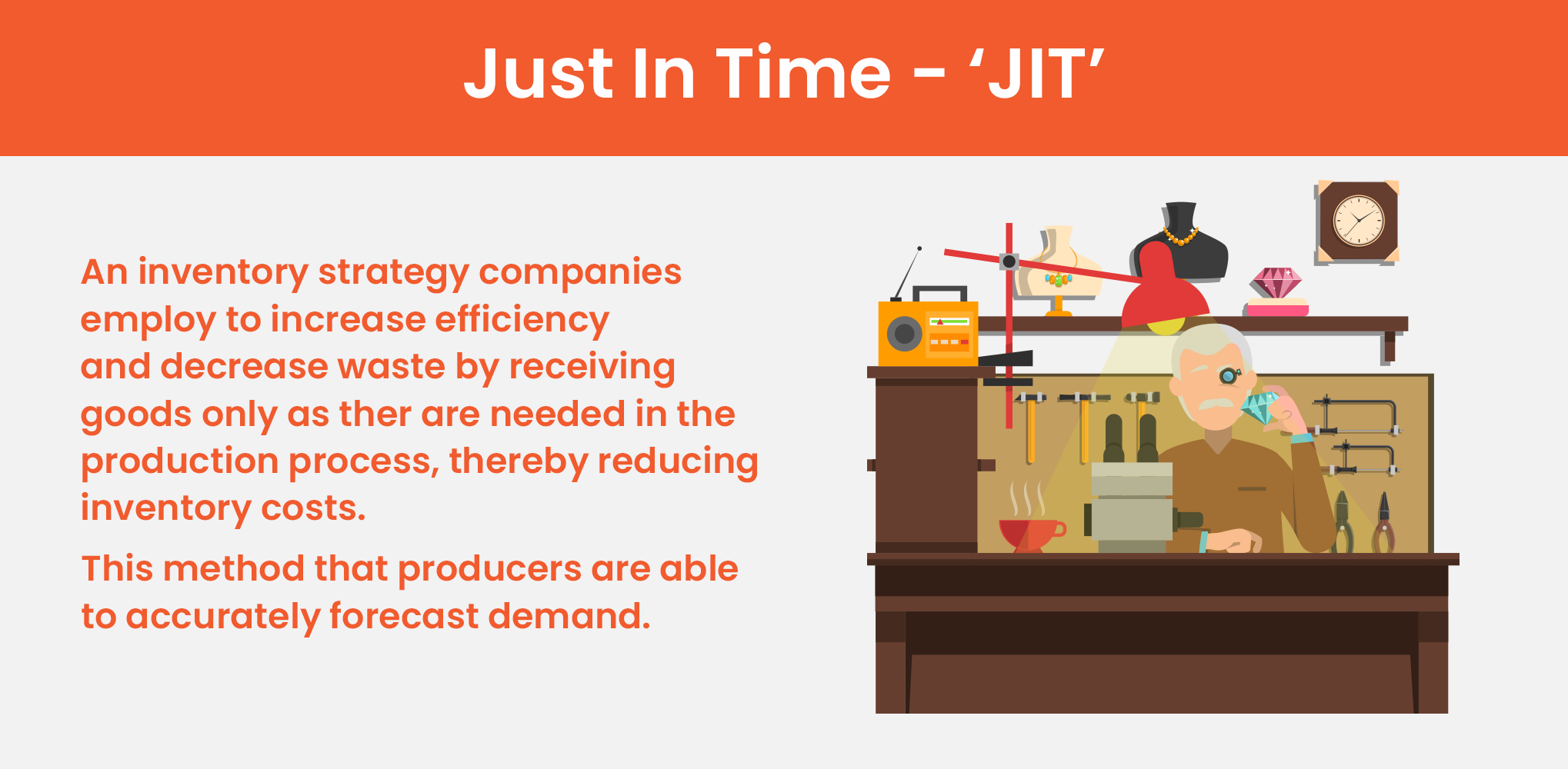

There are two automated methods to do this. The first is tracking the minimum inventory (required items), in which case if the inventory falls below a certain level, the system can notify the user, or it can send a purchase order to the vendor automatically. The other method is a job-based reorder method (items on job orders). This is an advanced functionality that solves two problems at the same time. First, it allows us to keep the raw material inventory on a minimum level, because we order materials when an order has been placed that requires that specific material, and second it continuously assures that there are no delays in manufacturing because we get an accurate forecast and we can order supplies in time.

The next thing that an inventory management system comes to our aid is automated inventory movements. In other words, we don’t have to manually assign raw materials to every order, as the system does this automatically. You can track exactly what you have in the safe, what’s on the production floor, and what’s on consignment. You can track in real-time how raw materials turn into finished goods, while the only thing you have to focus on is entering the correct weights in the system. I’d like to mention here that there are digital scales that read the weight of what’s placed on them and forward the information to the system automatically, minimizing the possibility of an error.

And we come to the next point, the tracking of inventory loss. Inventory loss can be a natural result of the production processes (polishing, casting), but it can result from other factors, for example, shortage due to theft. By tracking the inventory manually, these shortages usually remain hidden. Whether we do inventory adjustment or not when reusing scrap metal, if the tracking is not done automatically within a digitalized jewelry inventory software then most likely we will experience massive losses at the end-of-the-year stock count and many of these losses will be difficult to be backed-up with a valid explanation because they’re not traceable. In PIRO, for example, the loss is accepted only under a certain margin of error, if losses are higher than this, then the user needs to justify this.

A good inventory management software will help you with:

- Reduced inventory losses

- Increase visibility

- Reduce the problem of excessive inventory

- Forecasting

- Improve procurement and replenishment processes

Subscribe to Next Level Jewelry

C. Jewelry inventory management from purchasing viewpoint

I have already touched this subject, but it is worth turning back to it. There are several ways to automate purchasing and we can save significant time by this. For example, we can “command” the system to place an order automatically in a certain phase of the workflow – whether that is a manufacturing or a simple wholesale workflow. With this function, it is possible to order that piece of diamond from the vendor only when our customer has actually placed the order. This is a very common practice in the jewelry industry, most of the time the stones, diamonds, diamond rings being sold aren’t actually in the possession of the seller. Why? Because this way they don’t have to keep expensive stocks.

How can a jewelry management software system generate a purchase order automatically? The answer is simple: we can assign default vendors to certain item types, this way the system has every piece of information at disposal. The automated purchasing requires a maximum of 2-3 clicks from the user while doing this manually is a complex and time-consuming task.

A good inventory system will:

- Improve procurement and replenishment processes

- Monitor production trends

- Reduce the problem of excessive inventory

D. Jewelry inventory management from the pricing viewpoint

It is an organic part of inventory management that we know exactly what value our inventory represents, in other words, how much funds we have tied down in this form.

Market-based pricing is an excellent way to track this, the system automatically refreshes the substantive price of items on stock based on the prices of the world market, the metal market, or Rapnet prices if there are diamonds on stock. All of this happens automatically and in real-time. Not all jewelry inventory software has this functionality though.

But in the case of inventory items, it is not only the price of raw materials that is important but also the pricing of the finished product. This happens based on different principles at every jewelry business, that’s why it is important to use formulas in a software environment as well.

Smaller businesses that don’t use software try to replace this with Excel formulas. In PIRO we are prepared to handle these different pricing formulas. Component-based pricing, attribute-based pricing, factor-based pricing, cost-based pricing – these are only a few of the handled pricing formulas that help in pricing jewelry correctly. These formulas allow us to create precise, effective and quick pricing. For example, if we are creating a price quote, but want to replace the center stone of the given style, then we don’t have to recalculate the price, because the system is capable of calculating the new price based on the new stone’s attributes. We call the mechanism behind this: variants. This means that we have a basic style, the components of which we can replace – 18k Pink instead of 14K Yellow, for example, and the operation affects the base price.

A good jewelry inventory software will:

- Manage inventory valuations and costs

- Increase visibility

E. Jewelry inventory management from the accounting point of view

Inventory automation is especially important from the point of view of accounting because we need to be aware of every single momentum. What came in, what went out, what we have on stock, what we need to order – the 4th question may be the most important.

These movements show us what direction our business is headed to. Many sales, but the margin is too small? Many unsold items on inventory? Increasing or decreasing sales? Perhaps stagnating for the past few years? Do we have high sales rates, but many assets, unpaid checks? Maybe there’s nothing wrong with my products, more like I have bad customers.

I have some bad news for you: QuickBooks is not an inventory management software. Many companies try setting up their inventory tracking in QuickBooks, and this usually ends with disappointment. QuickBooks does an excellent job of tracking the financial part of the business, but the inventory module it comes with wasn’t made for the jewelry business, quite simply it is too general for that purpose. This is why we do the inventory accounting part of the business in PIRO and send only the financial information over to QuickBooks with our plugin called QuickBooks Bridge, which happens automatically and in real-time. This allows keeping the inventory-related automation in PIRO while Quickbooks can handle all the financial accounting, as needed.

Subscribe to Next Level Jewelry

Looking for jewelry inventory software?

I hope you got some valuable information and I managed to pass on a few thoughts that help you widen your perspective regarding jewelry inventory automation. Every jewelry business is different, some have a simpler inventory, others are more complicated, but automation saves a lot of time and energy in both cases. I'm happy to do a one-on-one consultation with you if you struggle to find and implement the right system in your jewelry business.

You can pick a date and time here: gopiro.com/demo

FAQ: 5 Key questions on automated jewelry inventory management

- Why is manual inventory management risky for jewelers?

High-value inventory is prone to loss, stockouts, or overstock situations. Manual methods, like spreadsheets, often deliver outdated information, leading to poor decisions. Inventory automation ensures accuracy and visibility. - What essential benefits does jewelry inventory software offer?

It enables optimal inventory levels per location, reduces losses and overstock, supports demand forecasting, enhances visibility, and optimizes procurement and replenishment workflows. - How can automation improve inventory visibility?

By grouping items (such as rings by size or pendants by length) and tracking their location - warehouse, store, consignment - it becomes easy to know what’s sellable now and what’s reserved elsewhere. - How does automation support manufacturing and prevent stock issues?

Advanced systems auto-generate purchase orders when stock hits minimum thresholds or allocates raw materials for job orders - ensuring production flows smoothly without manual tracking. - Why is dynamic pricing automation important in jewelry inventory management?

Materials like gold and diamonds fluctuate in price. Inventory software that updates item values based on world metal market or RapNet prices ensures real-time cost accuracy - making spreadsheet-based pricing obsolete.