A short history of ERP systems

Jewelry ERPs are part of a category of software products called Enterprise Resource Planning. Also called ERP it is a software that is built around your business processes, it is a collection of utilities, concepts, and technologies that serve the purpose of unifying and automating all aspects of a business – basically anything that can be digitized, stored and processed with respect to a business’ minute-to-minute and day-to-day operations.

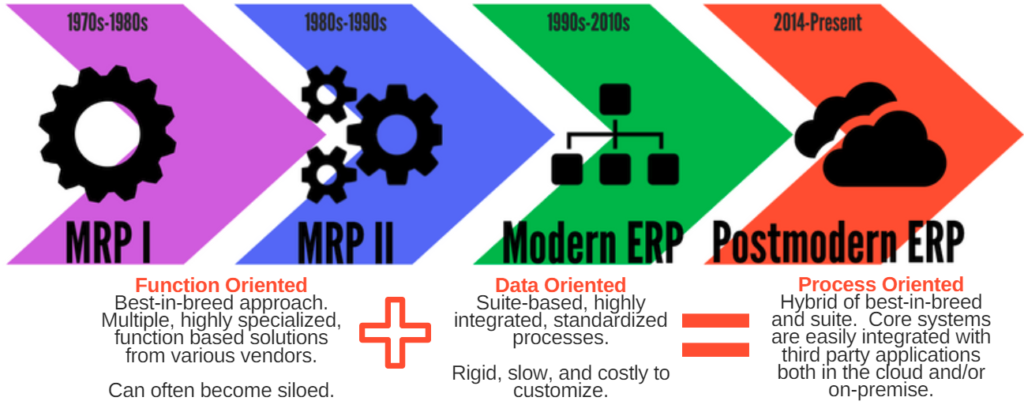

ERP is the current evolution of resource planning tools that began when computers were applied to materials planning for production. It is the natural evolution of the Bill of Materials (BOM) planner, project planning that leads to the latest evolution of operational planning systems called ERPs.

ERP mirrors the function of operational planning and control and combines them with all of the other business functions to create synergies and a knowledge based management environment.

Evolution of ERP:

source: 4acc.com

These days having an ERP for a large company is not optional anymore – they simply would not exist without one, and even mid-sized and small businesses feel the need to catch up as companies of every size and shape are introducing ERP systems. The reason why smaller companies also want to implement ERPs is to gain advantages and become more efficient so they can sell more.

Video on Next Level Jewelry with Zsolt Torok

Subscribe to this YouTube channel

How do ERP systems provide such an advantage?

If you think about it, what is the goal of any manufacturing business? Not just jewelry, but other businesses as well. Or rather, what should be the goal (as it is not always)?

The goal is to get products to the customer in the most direct line and the fastest way possible while making a profit. Now, the profit part is interestingly not the most important part here – profit maximization will be the subject for another of my articles and videos. What is IMPORTANT here is that anyone who can create a more direct line from the idea – the thought of the customer to buy or get something made – to the customer WILL do better than others – it’s as simple as that.

The direct route matters – the more detours or stops you have to make along the way, the more your revenues will fall and the more money you will lose. ERPs can create this direct route by integrating the different areas of your business into a data highway while making sure that any stops in the process are minimized. The key word here is “can” – as that is, unfortunately, very often not the case. Let’s find out why?

First, it’s important to know that there are two distinct types of ERPs – generic ERPs and industry-specific ERPs.

Generic ERPs and industry-specific jewelry ERPs

Generic ERPs, such as Oracle, SAP, Navision, and so on – are usually very large, complex systems built mostly around financial concepts. They have tightly integrated modules, all geared to support the accounting side of the business. They are built around traditional business functions such as sales and manufacturing and accounting. Generic ERPs have a fixed structure and your business needs to adapt to this. They were designed with top-down thinking and if you are willing to change the way you work then it might suit you. However, over time your company will grow and you might want to change things and when the time comes the upgrades for the generic ERP will be quite expensive.

Generic ERP systems that can perform general tasks well but are not particularly useful in any specific industry without extensive customization. These customizations are very expensive, performed by outside consultants who may or may not have a good understanding of that industry – and all this will add to the implementation costs. Also, since they are not specialized on anything, they have user interfaces that can get overly complex, even for performing simple things.

On the other hand, there are the specialized ERPs - these are systems that have been built for an industry, with that industry’s best practices and unique use cases in mind. Industry-specific ERPs tend to follow a bottom-up approach.

They get to know the industry and then your company. Their approach is based on making sure that the software will work in your advantage. Future change requests are also easily implemented as vendors are continuously working on solutions that are relevant to your specific industry.

Beware that there is a distinction between so called vertical ERPs and industry-specific jewelry ERPs. While vertical ERPs might seem specialized because they promise industry-specific customization, in reality they are generic ERPs addressed to a wide variety of industries. If you see that an ERP is addressed to several different industries on their website then it’s not an industry-specific ERP. Industry-specific ERPs are not just “made to fit”, they are the real deal.

Subscribe to this YouTube channel

Jewelry ERP

You should NOT opt for a solution that is not jewelry-specific – you have to get something that was built for the jewelry industry from the ground up.

The reason is that the jewelry industry, and jewelry manufacturing, in particular, is very complex. Making and selling jewelry is part craftsmanship, part manufacturing, and part marketing – so you need a system that blends these together seamlessly.

This is especially true when you are dealing with custom jewelry: since every piece is different, there can be literally millions of variations and possibilities, and a system that does not accommodate for this variety of components and style will not be very useful to you.

Most jewelry can be fairly expensive, and you end up needing a system that is not only jewelry-specific but can also deal with the complexities of pricing these custom pieces and keeping track of them in your inventory or your stores, not just until they are sold, but even afterward, when you have to make repairs or copies.

How to pick a jewelry ERP for you company?

1. Prepare a list of functionalities that you need

This list should be divided into ‘Must have’ and ‘Nice to have’ categories. Must have items are things that need to be resolved or at least alleviated by the introduction of the ERP system; the “nice to have” items are functionalities that could make some business processes easier but you can live without these for the moment. This list of items will be very helpful when you are trying to narrow down your list of potential software solutions to no more than five potential candidates.

2. Check how jewelry-specific the system is

Every industry has its own specific items and processes that need to be tracked. Obviously, a car manufacturing software will not work for the manufacturing of jewelry due to the different specifics that need to be tracked. For example you might need to track processes starting from CAD design to 3D printing, casting, molding, polishing, stone setting, engraving and even finishing. These are unique services of the jewelry industry, therefore implementing a generic ERP might not be the best solution for your company.

The disadvantage of generic ERP systems is that they are nearly impossible to customize to the extent that the respective industry requires. Generic ERP systems are usually implemented by large corporations with pretty standard, mostly financials-related processes (as these are usually the same for every industry) and for whom there is no distinct advantage in using an industry-specific ERP – think food distribution or shipping services.

A good example for generic ERP would be a platform like Navision or by its most recent name, the Dynamics 365 ERP platform that is already present in the jewelry industry as well. These systems can be easily spotted by taking a closer look at the clients they have worked with. If they have a lot more clients outside the jewelry industry than inside, that means that they are not specific to anything, and are rather a generic ERP solution masquerading as a specialized one; so you should watch for these signs.

3. Flexibility versus the need for custom programming

As we know no two companies are alike so even if the system is jewelry-specific, a certain amount of customization is needed, maybe the layout of an invoice or re-arranging fields on certain printed forms to match your existing paperwork.

In any case, it is worthwhile to check whether your top five potential software choices can be highly configured without any programming (such as adding workflow steps, creating your own type of jewelry from components, setting up your own pricing structures, and so on) or rigid, so-called out-of-the-box solutions.

Unless you are working in a niche market with some very different needs than most other companies, the amount of customization will range somewhere between 10 and 25 percent of your total cost - anything above this is considered extreme customization and can be regarded as a sign that you chose a less optimal solution.

4. Your client base (these would be the majority of your customers)

You should pay attention not to be fooled by a software that is trying to advance vertically.

„Many business software vendors pass off their solutions as being industry-specific however they will use another vendor's front end to create the illusion of having a very specific fit for your business.” - Engineering News

This would be for example a platform like Navision or by its most recent name, the Dynamics 365 ERP platform that is already present in the jewelry industry as well. These systems can be easily spotted by taking a closer look at the clients they have worked with. If they have a lot more clients outside the jewelry industry than inside, that means that they are not specific to anything, and are rather a generic ERP solution masquerading as a specialized one; so you should watch for these signs.

5. Integration possibilities

Integration is basically the practice of connecting one system to another. The latest generation of ERP systems, also known as postmodern ERPs, are process oriented and their best-known characteristic is that they can easily be integrated, or connected to other systems.

The typical setup for such a system is that there is a subsystem for every activity and process, like accounting, shipping, customer management, or online sales. It is extremely important that these systems can be connected because managing parallel systems can be very time-consuming if they don’t talk to each other.

My personal experience is that more and more companies that get in touch with us consider an excluding factor if our software cannot be connected with their website or let’s say, QuickBooks, which is the most popular bookkeeping software amongst jewelers.

The possibility to integrate is an increasingly important question, but the way of integration also plays an important role. There are two main technologies for businesses to exchange data electronically: EDI, or electronic data interchange, and API, or application programming interface. I will get into more details on these in more in one my other videos, but what you should know about them is that EDI was considered a pioneering technology in its own time, but now it’s about as useful as a fax - compared to this the API is getting more prevalent, as it’s much more flexible and it allows for real-time data transfer, which is hard to do with EDI.

6. Technology used

Now, you don’t have to know the newest or any programming languages, in most cases, you can see which software is outdated simply by looking at them. The interface, integration possibilities, possibility to customize, flexibility all signal how up-to-date the software is.

Many companies claim to be working in the industry for 20-30 years, but if they haven’t placed their solutions on new platforms, then it may be very possible that they are promoting an outdated system.

It may be worth considering cloud-based solutions because many consider cloud-computing the technology of the future and they are gaining more popularity in the jewelry industry as well.

Dangers of NOT choosing a jewelry-specific system?

1. Extensive customizations lead to high costs

Generic ERP systems would require a lot of add-ons and customization in order to work properly for a specific industry. Larger corporations may be able to afford the extra costs of such customizations, but small and mid-size businesses can rarely spare these expenses.

The catch usually is that at the beginning of implementation there’s only a very limited insight to the amount and level of customization needed – the devil, however, is in the details and those needs will be uncovered as the implementation moves along. Cost overruns in these cases are unavoidable and could overload the budget by as much as 80%.

The jewelry-specific software is designed with the industry standard workflows in mind, where the differences between companies require only minor changes.

2. Longer training curve

Generic ERP systems are complex and you need to adjust your business processes to fit the software which requires a longer adjustment period on behalf of your employees.

While industry-specific solutions are truly customer-centric. Since they are designed with the company in mind tailored to its unique processes, and usually end-users are already familiar with the processes that the software is built on.

3. Support issues

It is very important that those who implement the system and those who will provide support are familiar with the industry. It is not enough to understand the programming language, to solve certain problems, one needs to have a deep understanding of the industry itself. This is another advantage of an industry-specific software.

4. Update issues - high maintenance fees

In the case of generic systems, software updates are always a red flag. What happens when the ERP vendor updates its system?

You may have to purchase a new license for the new version (like you have to do for Navision, for example) and you would also have to wait for your integration specialist to come back and customize your software again as much of the customization may break with the update.

One of the best examples is again the case of Navision which was further developed by Microsoft. Several large jewelry companies adopted Navision but then a core update made it incompatible with earlier versions.

This resulted in huge costs for these companies, both in development and lost revenue - because of many of them have abandoned Navision and turned to jewelry-specific software such as our own PIRO.

Summary

As generic ERP systems require extensive customization more and more companies are turning towards industry-specific solutions (such as our PIRO).

There are quite a few software systems that have been developed along the lines of being jewelry specific so make sure that the one you choose is truly jewelry specific, flexible enough to accommodate minor changes and is updated regularly.

However, there are still a few jewelry ERP systems out there that are relatively accessible for midsize and small companies and can be quite useful in the right circumstances – however you really need to make sure that whatever system you select for your business, it will be able to change and grow as your company changes and evolves.

So the choice is yours: Do you want to fit in or stand out and keep your business moving forward?

Thanks again for reading this article on jewelry ERP or watching Next Level Jewelry – if you found this helpful in any way I hope that you will subscribe to my channel and that you will come back to see more videos about how to make your jewelry business better!

Subscribe to this YouTube channel

FAQ: Jewelry ERP vs. Generic ERP — 5 key insights

- Why are generic ERPs a poor fit for jewelry businesses?

Generic ERPs require extensive - and costly - customization to handle jewelry-specific needs, such as pricing custom pieces, tracking gemstones and metals, or managing repairs, resulting in bloated costs and complex upgrades. - What makes jewelry ERPs inherently different?

Jewelry ERPs are built from the ground up to reflect the industry's unique workflows: from custom design variations, style components, to repair tracking - without needing massive configuration or coding. - How can you tell if an ERP is truly jewelry-specific?

If the vendor's product targets multiple industries and you see heavy generic branding, it's likely not truly jewelry-specific. A real jewelry ERP focuses exclusively on industry nuances and practical use cases. - Why is flexibility without coding essential for customization?

A good jewelry ERP allows users to configure workflows, invoice layouts, and pricing structures, without having to code. This supports easy future changes while reducing reliance on expensive developer interventions. - How does PIRO stand out as a jewelry-focused ERP?

The blog notes that when large generic platforms like Dynamics/Navision require costly upgrades and reconfiguration, many jewelry businesses migrate to jewelry-specific systems such as PIRO, built for flexibility, clarity, and seamless industry alignment.